Welcome toSinaran Megamas

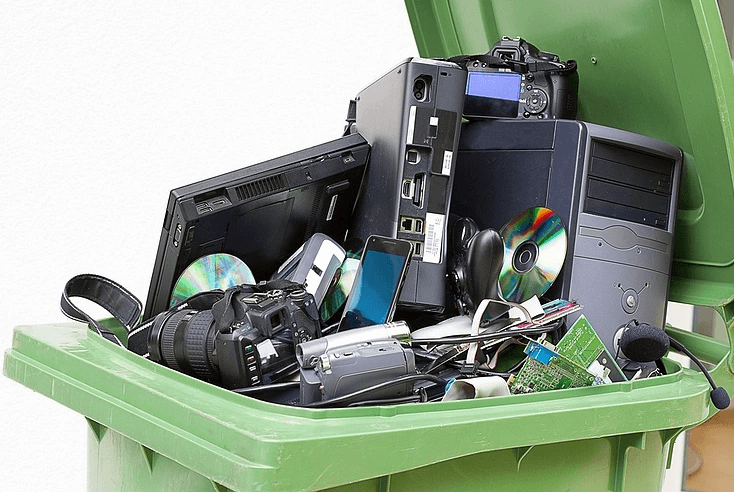

Going green is our company business...

Sinaran Megamas Recycle is 100% local company Alex Tan Kim Guan ( PBM BKT ), Managing Director and Andrew Tan Woei Long Executive Director more than 30 years involve in all kind of general electrical and electronics, Based in Malacca.

In realizing our strength, expertise and well established networks; all of us believes we will be more professionally acute and more efficient in recycling waste for our Government Agencies in Malaysia.

The company's vision is to be more dynamic in recycling indsutry as one stop waste management for all level's of waste generator to attract more confident from business partners.

Full recycling services with our client's interest at heart, we provide customized solutions according to their requirements and other services in the related field.